TRACKING PULLEYS

POSITRAC® conveyor belt tracking/cleaning pulleys are fully machined steel and are proven to out-drive rubber-lagged pulleys, track conveyor belting, and continuously clean the inner face of the belt.

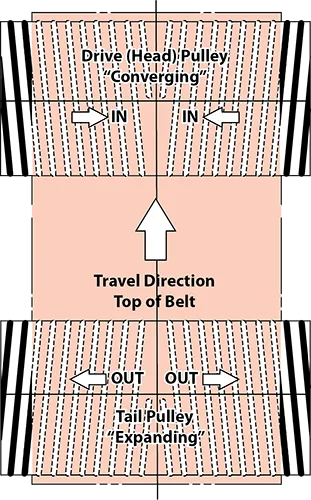

We make the pulleys to order in standard sizes, so the change from smooth pulleys to tracking pulleys is very easy. For most conveyors, all that is needed are two helical tracking pulleys, one at each end. For an existing conveyor, you simply replace the smooth pulleys with the POSITRAC® pulleys. If you order a new conveyor from a vendor, just specify the Dynaloc pulleys at the head and tail positions. The pulleys are made of steel, aluminum, and all stainless steel construction.

Positive belt tracking and drive traction eliminate edge fraying of the belt, lagged drive pulleys, and downtime for replacing prematurely worn-out belting and pulleys. Also, high belt tension is not needed for good tracking, which eliminates excessive belt stretch, lace failures, crown wear, bearing, shaft, and end plate failures. Our dual helix tracking/cleaning pulleys are proven to save money on operating and maintenance costs.

Normal lead time is 5-10 working days; FOB is our plant here in California. The standard list price includes Taper-Lock hubs and bushings or bored hubs with keyways and set screws. We can also provide bearings, welded-in shafts, or other types of end fittings.

Dynaloc Thin Film Style Positrac Pulleys

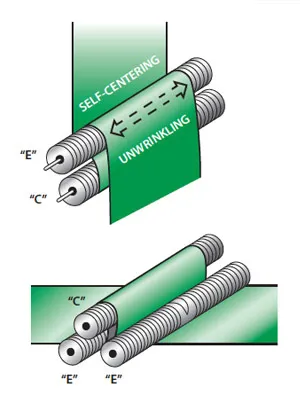

Dynaloc's line of Thin Film Pulleys has finally made it possible to have reliable tracking of thin films and belting without the complexity of edge-sensing and extra control devices. The patented Dynaloc integrally machined dual helix provides inherent tracking stability as the expanding dual helix unwrinkles thin films. These Positracs outlast rubber-lagged pulleys, and they automatically clean the inside of the belt.

You can use them on all closed-loop belts or continuous strip process lines. They are made to provide instant initial belt centering adjustments. We have thin-film configurations for tracking every type of belting, process strip, packaging film, or paper, and all work at extreme temperatures.

Types:

I HP1- These pulleys were designed for maximum driving traction and self-centering of thin belting, process strips, and some plastic films or sheeting. This configuration is particularly effective in driving and tracking such slippery materials as Teflon-coated fiberglass, synthetic fabric belting, plastic surfaced belting, etc.

VTF- These Dynaloc Thin Film Pulleys are mainly used to track coated films, plastic sheeting, belting, packaging films, emulsion, and adhesive coatings. These special VTFs do not provide as much driving traction as the IHP3s because they were designed to have a very gentle interaction with relatively fragile, thin materials; however, they are very effective in eliminating air pockets in lamination.

BELT CLEANING PULLEYS

The best method of continuously removing contaminants from your belting.

Patented

The expanding dual helix cleaning pulley can be used in conjunction with the converging Positrac head pulley for good drive traction, tracking, and cleaning. It can also be used by itself just for cleaning and steering.

The cleaning pulley is fabricated from all stainless steel with welded-in stainless shafts and sanitary end plates for food service. For non-food service, the cleaning pulley is fabricated from carbon steel.

One end of the shaft is drilled to allow water, steam, or air to fill the inside of the pulley, pressurize, and exit through the holes in the face of the pulley, providing continuous belt cleaning. The cleaning pulley is priced on application and can be supplied with or without the rotary pressure joint. A dual-flow rotary pressure joint is also available to recirculate ( no holes drilled in the face) hot water in the cleaning pulley to help melt away contaminants such as grease or ice.